Pairing Rooftop Solar with Warehouse Robotics – Harnessing Synergy Between Technology and Sustainability

Logistics Viewpoints

FEBRUARY 4, 2025

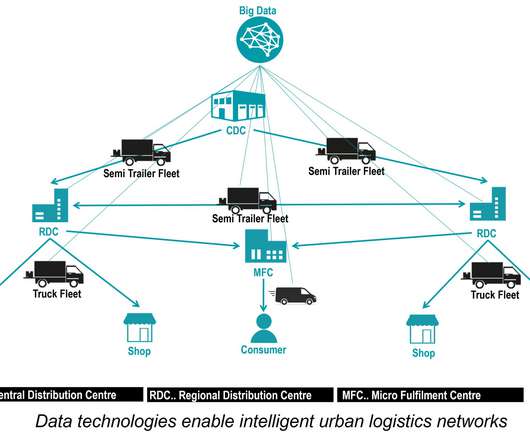

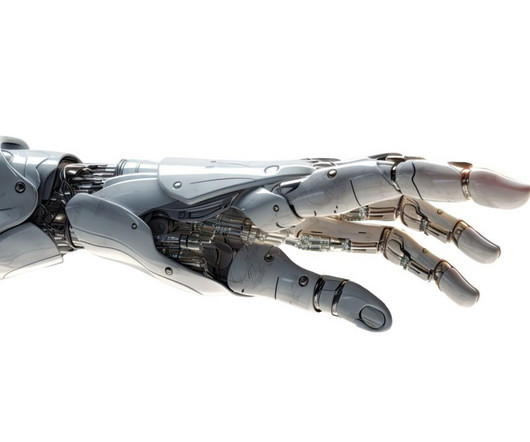

Source: mainebiz.biz In today’s rapidly evolving logistics and supply chain sector, warehouses are increasingly turning to innovative technologies to gain a competitive edge. has over 450,000 warehouses and distribution centers, with 16.4 AMRs operate with autonomy, navigating complex environments using real-time data.

Let's personalize your content