Supply Chain AI: 25 Current Use Cases (and a Handful of Future Ones)

Logistics Viewpoints

NOVEMBER 4, 2024

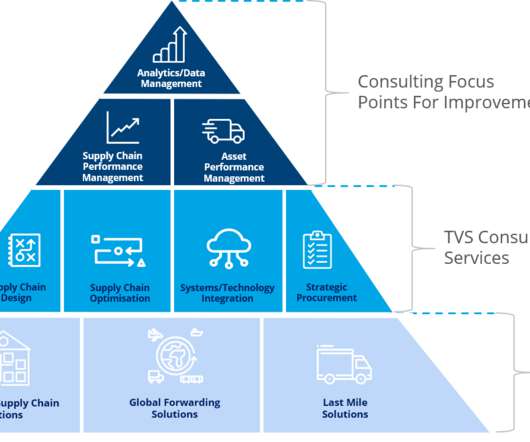

In mathematical terms, optimization is a mixed-integer or linear programming approach to finding the best combination of warehouses, factories, transportation flows, and other supply chain resources under real-world constraints. ML can also be used to generate labor standards for warehouse workers.

Let's personalize your content