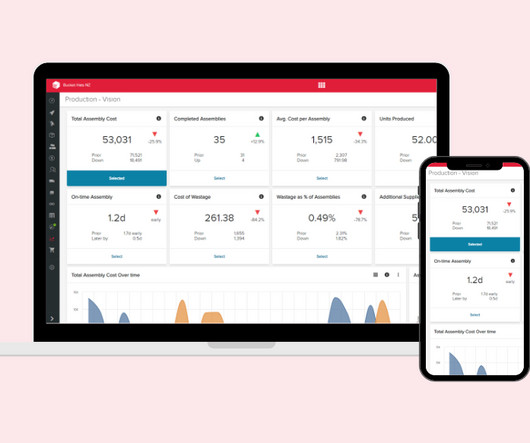

Using data and AI to improve manufacturing

SYSPRO Smarter ERP

JULY 3, 2023

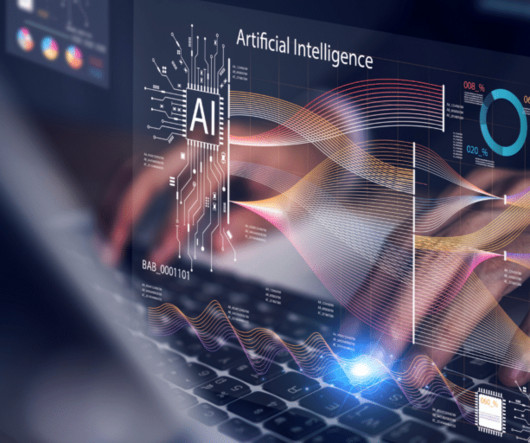

Using artificial intelligence (AI) in manufacturing can significantly improve productivity, reduce equipment failure, increase production efficiency and help identify new business opportunities. The area of AI that manufacturers need to explore to drive their factories into the future is machine learning (ML). The Industry 4.0

Let's personalize your content