Gain a Leading Edge in Inventory Management through Digital Transformation

DELMIA Quintiq

SEPTEMBER 22, 2021

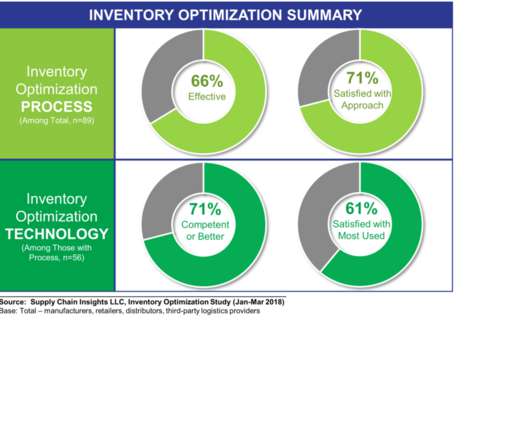

An increasing lineup of advanced digital solutions have given manufacturers the edge to transform and achieve better inventory control. The manufacturing industry is constantly searching for new and inventive ways to improve inventory management. Types of inventory that can be optimized.

Let's personalize your content