The Internet of Things and Supply Chain Transformation

Enterra Insights

SEPTEMBER 24, 2018

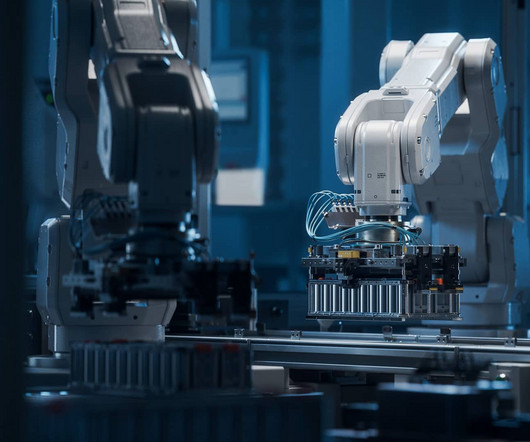

Recent reports indicate Internet of Things (IoT) technology adoption is slowing down due to security concerns. … Every supply chain business, from manufacturing to logistics, should be taking a close look at the Internet of Things now.”[4] As I noted in a previous article, caution is warranted.[1]

Let's personalize your content