Supply Chain Sustainability Gathers Steam

Logistics Viewpoints

MAY 25, 2021

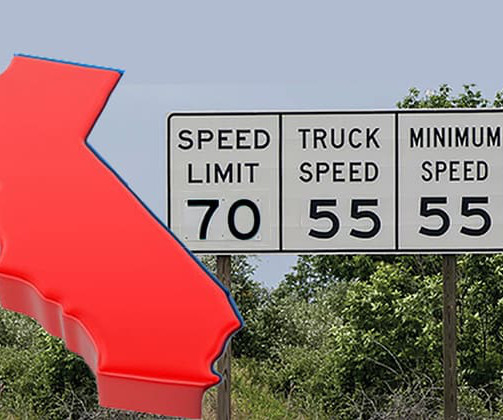

The global supply chain is routinely beset by challenges, both large and small, but the past couple of years have delivered a string of significant logistics disruptions that have threatened to upend the tightly choreographed dance of global freight transportation. More and more large U.S.

Let's personalize your content