The Impact of NIS 2 Regulations on Manufacturing Supply Chains

Logistics Viewpoints

NOVEMBER 6, 2024

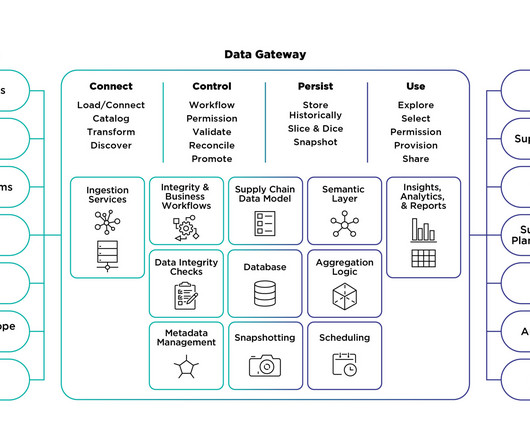

NIS 2 Has Deep Impacts on the Supply Chain, Not Just Plant Operations The manufacturing industry is undergoing a significant transformation as it grapples with the implications of the Network and Information Systems Directive 2 (NIS 2). Manufacturers must now assess and bolster their cybersecurity measures to comply with the directive.

Let's personalize your content