Demand Planning: Whipped And Chained by Tradition

Supply Chain Shaman

SEPTEMBER 13, 2023

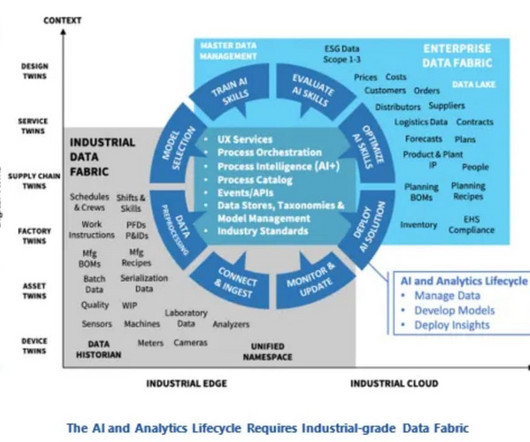

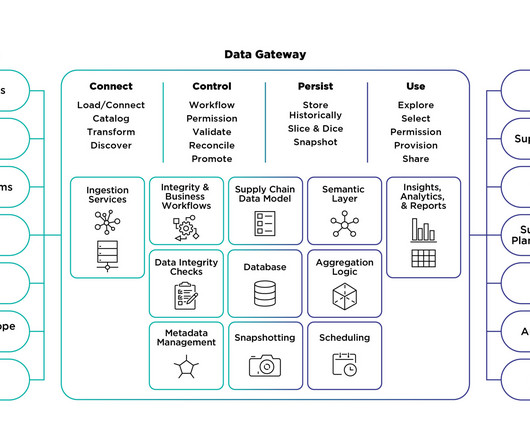

She wrote, “I have been working in the supply chain for 35 years, and we are still trying to solve the “demand” issue. Solving from a supply side seems to work for many companies I work with. Over the last two years, I actively engaged technologists and business leaders to redefine demand planning.

Let's personalize your content