Winning strategies for distributors and manufacturers during an economic downturn

EazyStock

MARCH 14, 2023

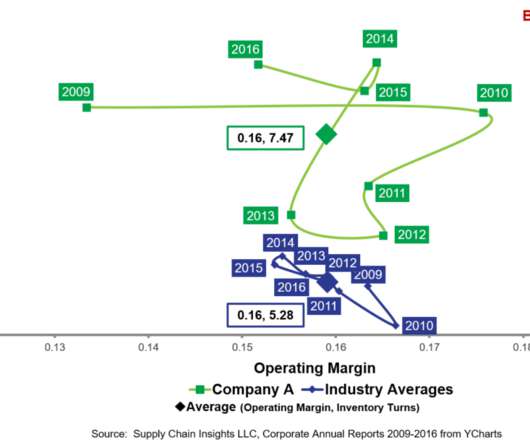

Rapid cost increases, interest rate hikes and reduced demand require more effective inventory management and forecasting attention. What the last recession taught us An article from McKinsey & Company (2022) analyzed the performance of about 40 publicly traded distribution companies during the 2007-2009 recession.

Let's personalize your content