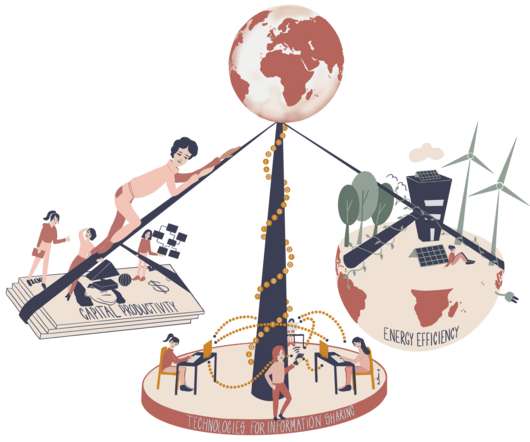

3 Powerful Ways Procurement will Drive the 2030 Saudi Vision Transformation

ivalua

MAY 30, 2023

Ivalua Spend Management Insights [ivory-search] 3 Powerful Ways Procurement will Drive the 2030 Saudi Vision Transformation May 30, 2023 | | Procurement Strategy by Sara Omer What is the Saudi Vision 2030 Program? The Saudi 2030 Vision invests in the community to drive local business growth!

Let's personalize your content