Managing Supply Chain Disruptions: U.S., U.K. Manufacturers Accelerate Procurement

ivalua

JULY 14, 2022

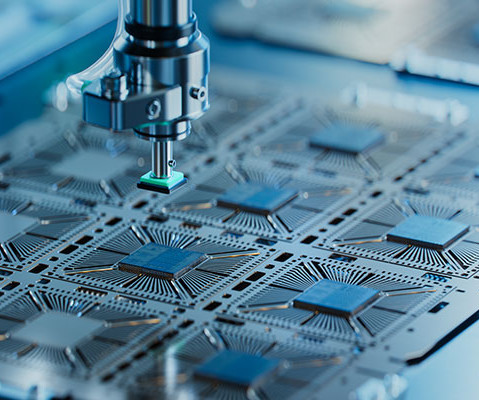

Ivalua study finds 97% of procurement leaders see significant disruption in direct materials supply chain; 67% not confident in existing technology; 84% consider modernization a ‘strategic priority’. A full 84% of procurement leaders agree that dealing with supply chain disruptions has been their biggest career challenge to-date.

Let's personalize your content