10 Ways A Data Gateway Improves Time to Value Across Your End-to-End Supply Chain

Logistics Viewpoints

MARCH 11, 2025

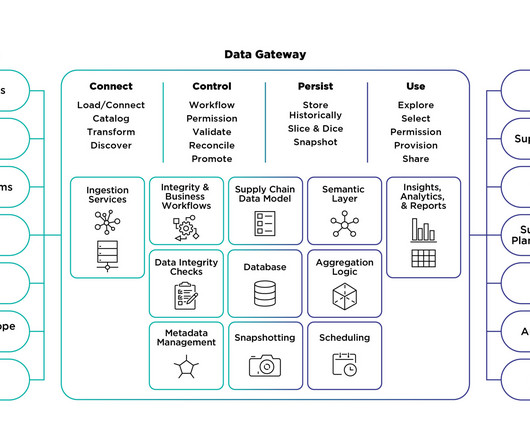

A data gateway is essentially a connective tissue across your supply chain, providing unified access to supply chain data from various sources, including enterprise systems, data feeds, data warehouses, data lakes, data marts, and business entities. Achieving these goals requires visibility into the entire supply chain.

Let's personalize your content