Sourcing Priorities: Low Cost Geography or Domestic On-shoring?

Supply Chain Game Changer

JANUARY 18, 2022

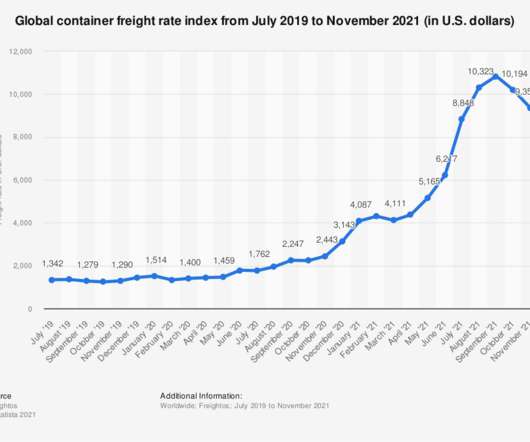

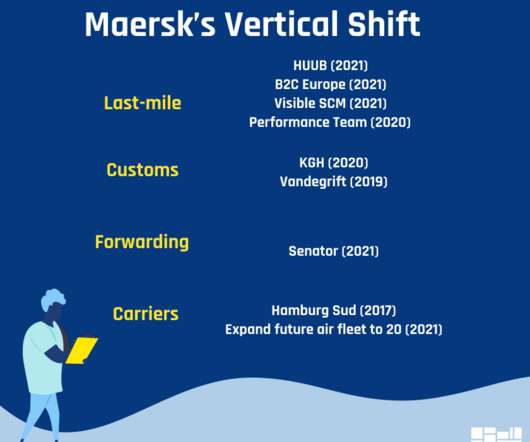

For many years the predominant priority in sourcing has been finding the lowest cost possible. However the continuity of supply issues caused by the pandemic has created a call to repatriate much of this manufacturing into domestic, albeit higher cost, regions. What is the appropriate sourcing strategy going forward?

Let's personalize your content