Give Analytics A Chance

Supply Chain Shaman

OCTOBER 25, 2021

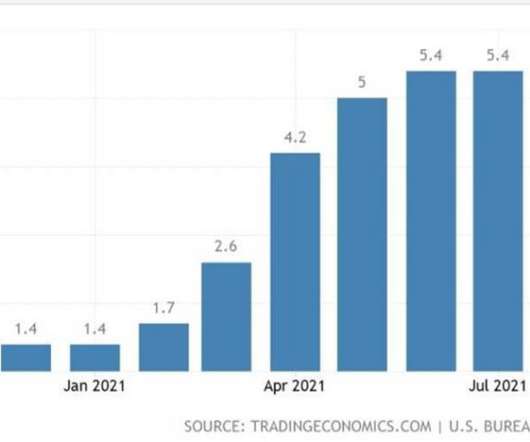

As supply chains scramble to keep up with the 32% net increase in the sale of products (physical goods), teams are reacting. Demand is outstripping supply: inefficiencies abound. Business leaders are simultaneously facing inflation and shortages. Labor, once assumed as available and a cost to be managed, is now an Achilles heel in the supply chain. As I read business periodicals and watch network news, the supply chain is headline news.

Let's personalize your content