Supply Chain KPIs & Metrics: Our Top 24 for Manufacturers

Silvon Software

JULY 22, 2022

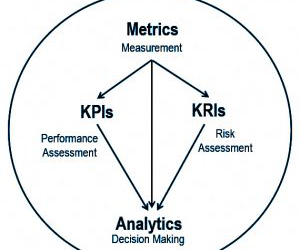

In fact, such KPIs are so crucial right now that the supply chain analytics market is expected to reach nearly $17 billion by 2027 as companies ramp up their supply chain performance management initiatives. Why is KPI tracking so important in supply chain management? Top-Line KPIs and Metrics for Supply Chain Management.

Let's personalize your content