Supplier Onboarding is Core to a Digital Supply Chain Transformation

Logistics Viewpoints

JANUARY 6, 2025

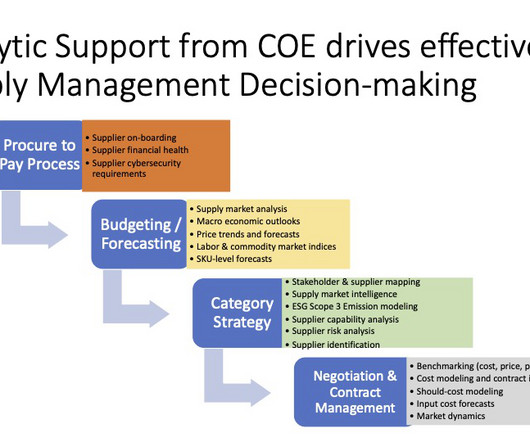

This collaboration allows for better optimization of the supply chain, ensuring the right products are available at the right time. Molex is a global electronics manufacturer that makes and sells over 100,000 distinct products – connectors, cable assemblies, and a wide variety of other products. But the work continues.

Let's personalize your content