ESG-Driven Supply Chains: Moving Beyond Compliance Toward Proactive Sustainability

Logistics Viewpoints

APRIL 30, 2025

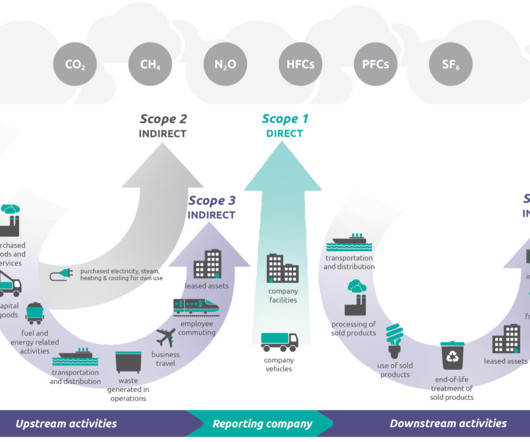

While past efforts focused on meeting compliance requirements, organizations are now working to proactively embed environmental, social, and governance (ESG) principles into their sourcing, production, and distribution activities. Without common definitions, ESG assessments can be inconsistent or incomplete.

Let's personalize your content