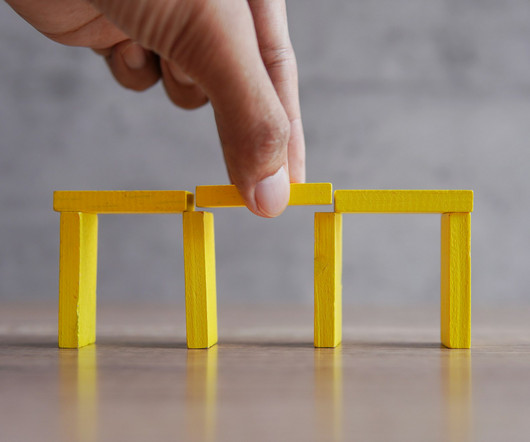

Bridging the Supply Chain Planning & Execution Gap

Talking Logistics

OCTOBER 17, 2024

Historically, there has been a disconnect between Supply Chain Planning and Supply Chain Execution processes and applications. As a result, companies tend to plan, optimize, and execute their inventory, labor, transportation, and warehousing operations separately (that is, in a siloed manner).

Let's personalize your content