Two less-obvious reasons why trucking capacity has remained so tight

CH Robinson Transportfolio

JANUARY 26, 2022

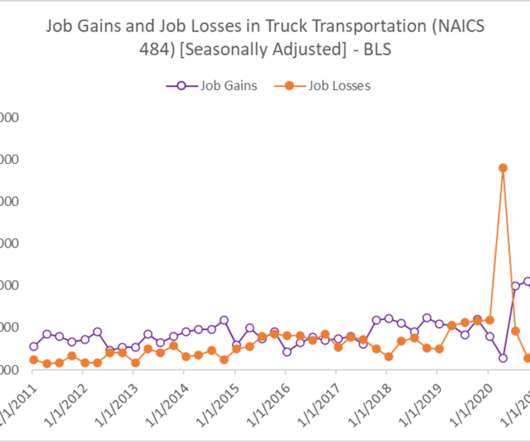

So we invited Jason Miller, associate professor of supply chain management at Michigan State University, to offer his perspective on the current state of trucking capacity. Shippers are likely to remember 2021 as the year with the tightest trucking capacity they’ve encountered in a long time. Two supply-side factors help explain why.

Let's personalize your content