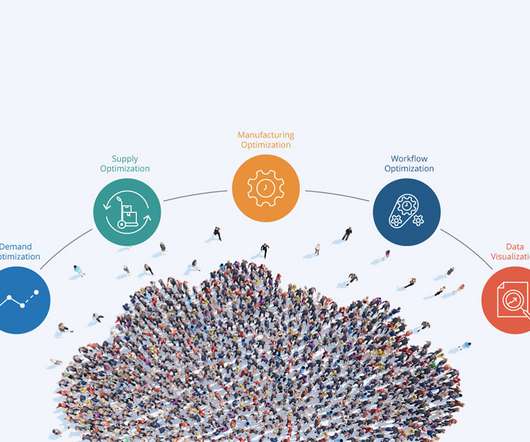

Reimagine Supply Chain of the Future – agile, resilient, and balanced – LogiSYM July 2020

The Logistics & Supply Chain Management Society

JULY 23, 2020

This year (2020) when they cancelled the Tournament, they stand to get 144 mil $ from Insurance company. Diversify supplier base : Supply chain should not be overly dependent on long lead-time or on a small pool of specific suppliers or sourcing regions. Identify sourcing plant/s which can back-up each other in times of disruptions.

Let's personalize your content