The Dire Need for Data Automation in the Manufacturing Industry | AFFLINK

AFFLINK

AUGUST 17, 2022

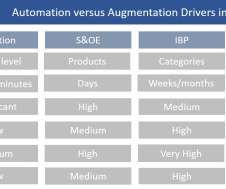

Automation in manufacturing can help be the driving force to lift some of the burden felt by many distributors across the globe. Upstream Supply Issues Manufacturers are struggling with the same product and shipping delays as consumers. Labor Shortages In warehouses, 73% of operators can’t find enough workers (Instawork).

Let's personalize your content