What are Digital Twins and How Can They Drive Warehouse Efficiency?

Logistics Viewpoints

MAY 11, 2023

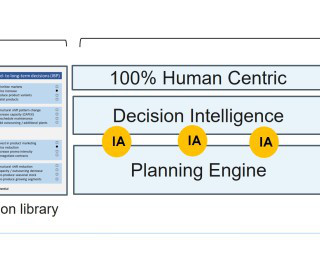

In the warehouse context, a digital twin can be created to represent the physical layout, inventory, equipment, and workflows of a warehouse. Inventory management Another area where digital twins can be beneficial is inventory management.

Let's personalize your content