GenAI Transforms S&OP: Better Alignment and Improved Employee Experience

Logility

OCTOBER 24, 2024

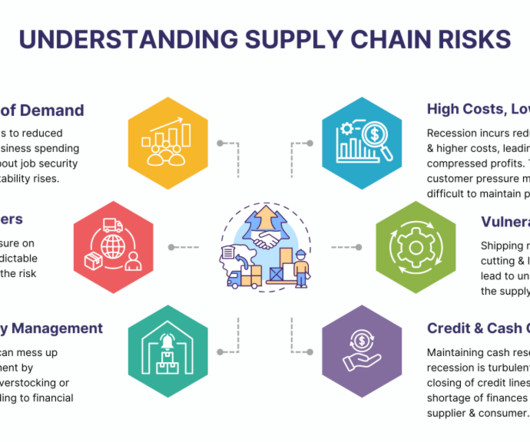

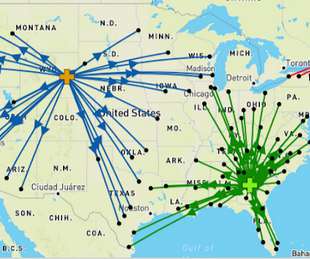

The groundbreaking technology is transforming how companies manage sales and operations planning (S&OP). S&OP provides the perfect starting point for companies interested in putting AI to work. A significant advantage of GenAI in S&OP is the automation of complex data analysis.

Let's personalize your content