Supply Chain Normalcy? Think Again.

Supply Chain Shaman

APRIL 18, 2023

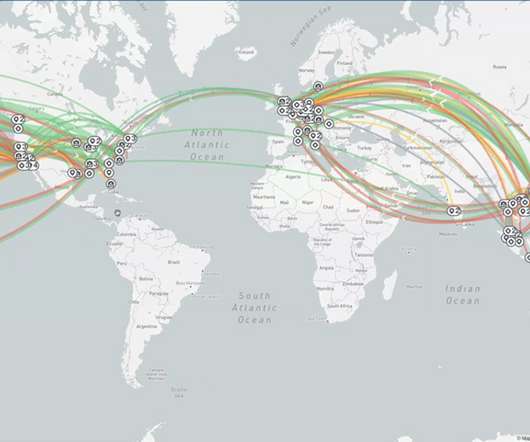

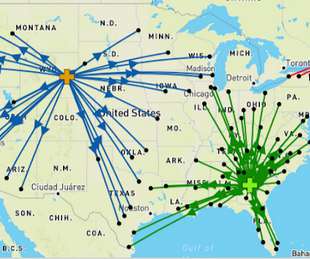

The global supply chain is built on three assumptions: rational government policy, availability of reasonably priced logistics, and low variability. For organizations layered in functional metrics and driving a cost agenda, this is a tough nut to crack. Build in-market sourcing. Over four-hundred days of war in Ukraine.

Let's personalize your content