Publix Vendor Guidelines Updated for On-Time Delivery

Zipline Logistics

MARCH 31, 2020

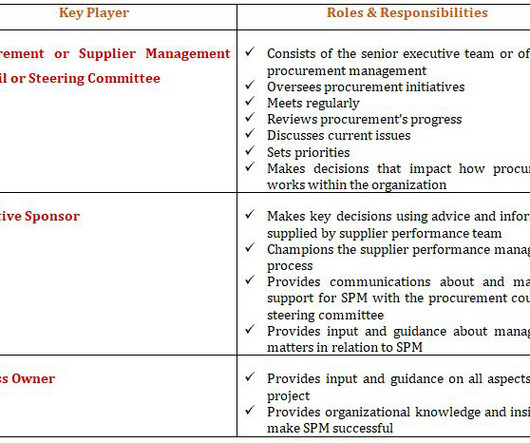

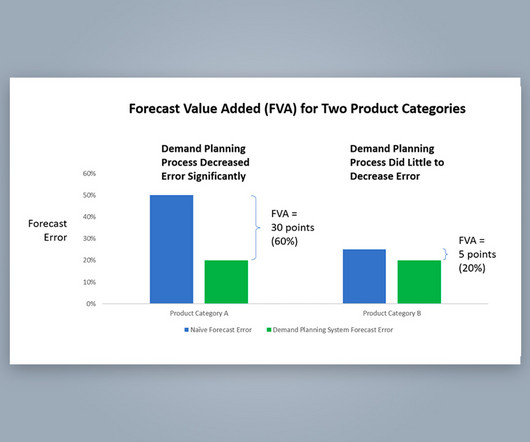

It measures on-time delivery performance and tracks metrics through a supplier scorecard given to all vendors working with Publix. . Publix calculates this metric monthly and reported to vendors. . Why Do Publix Vendor Guidelines Matter? . The reason for Publix’s program is protection against costly out-of-stocks.

Let's personalize your content