WMS and eCommerce: How to Use Supply Chain Technology to a Competitive Advantage

GlobalTranz

SEPTEMBER 21, 2018

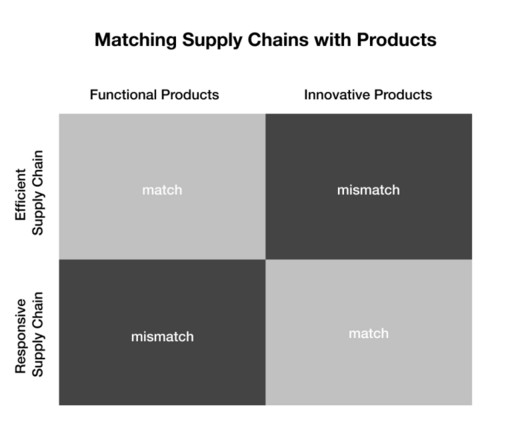

The application of supply chain technology is essential to maintaining a competitive advantage in the height of eCommerce growth. Warehouse Managers need to understand the challenges of maintaining a competitive advantage, how technology can help, and a few best practices in leveraging technology.

Let's personalize your content