Resilinc at ISM World 2025: Reinventing Supply Chain Risk Management with Agentic AI

Resilinc

JUNE 9, 2025

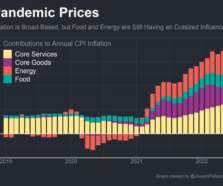

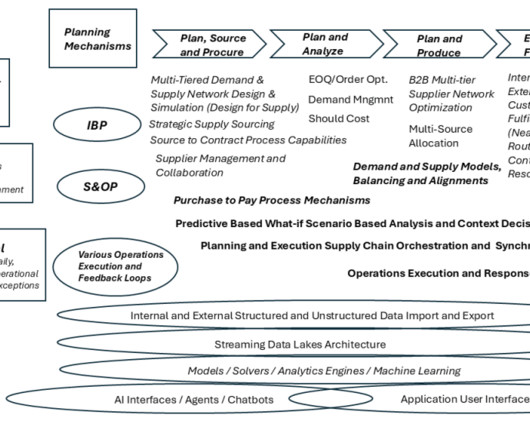

Resilinc made a powerful impact at ISM World 2025—highlighting how AI-driven foresight and financial risk intelligence can transform reactive supply chains into strategic assets. Both scenarios carry hidden dependencies, but overreliance on single or sole sourcing is increasingly a hidden challenge.

Let's personalize your content