Organizational Alignment: Overlooked, but So Important.

Supply Chain Shaman

DECEMBER 15, 2022

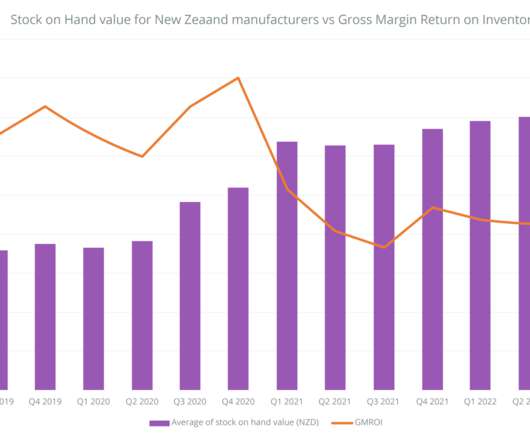

In the supply chain team analysis, note the 21% gap between procurement and manufacturing teams, the 35% gap between sales and operations and the 21% gap between finance and operations. Organizational Alignment in 2019. Functional Metrics. Organizational Alignment 2012. Gap closure requires leadership.

Let's personalize your content