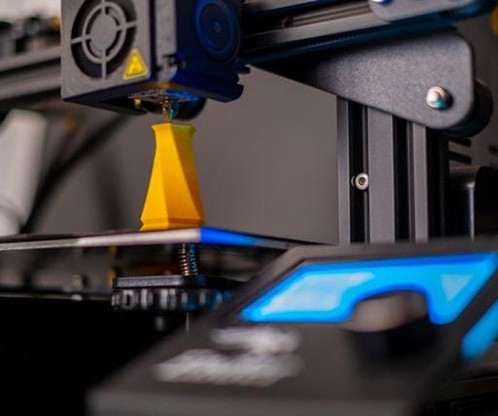

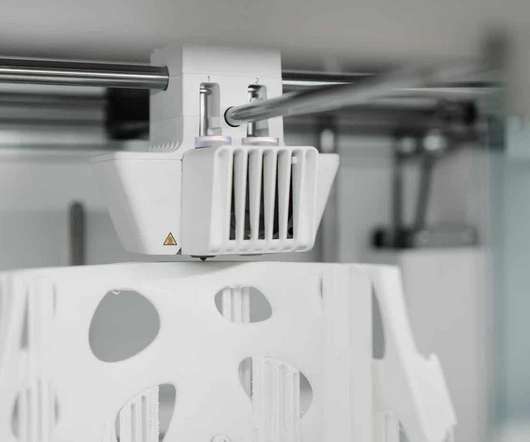

Revealing the Value of Additive Manufacturing in Aerospace and Defense

DELMIA Quintiq

AUGUST 4, 2020

What aerospace manufacturers need is agility in their design and production processes to help mitigate the variability in supply and demand. Additive Manufacturing (AM) is one innovation in which aerospace companies have significantly invested to try to address some of their unique challenges. What are the benefits?

Let's personalize your content