Climate Change and the Supply Chain

Logistics Viewpoints

AUGUST 16, 2023

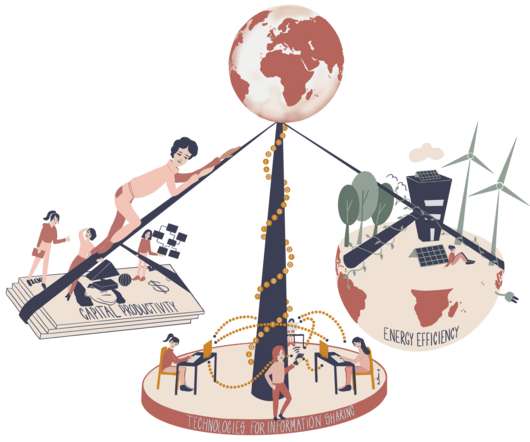

It’s good to see these companies recognizing the impact of climate change, and changing their policies, sourcing, and manufacturing practices to reduce emissions. Agriculture, oil and gas operations are major sources of methane emissions. Clearing land and cutting down forests can also release carbon dioxide.

Let's personalize your content