Lead Time Definition – How to Calculate & Reduce it?

SCMDOJO

DECEMBER 14, 2023

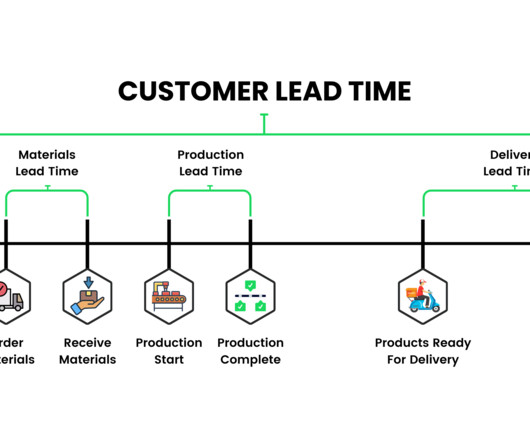

To make things simpler, having a clear lead time definition helps in making sure orders are fulfilled on time and customers are satisfied. With this in mind, we will explore in this blog the definition of Lead Time, its impact, and how mastering it can be your competitive advantage.

Let's personalize your content