Marshalling: The important last mile in warehouse management

SYSPRO Smarter ERP

MAY 29, 2023

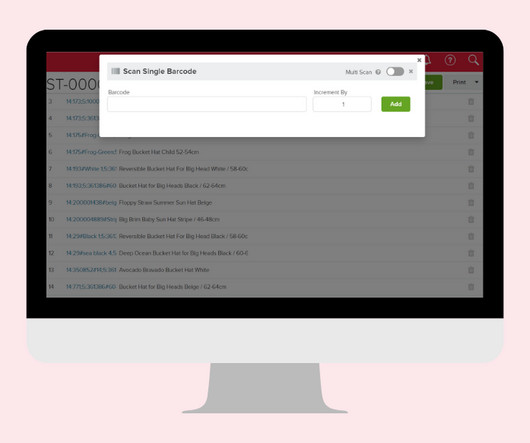

Marshalling in warehouse management refers to the process of arranging and preparing items for outbound shipment according to their destination and delivery schedule, as well as verifying their accuracy and completeness. What is marshalling in warehouse management?

Let's personalize your content