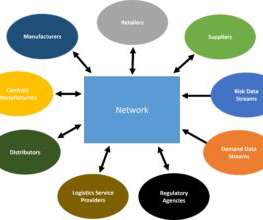

Supplier Onboarding is Core to a Digital Supply Chain Transformation

Logistics Viewpoints

JANUARY 6, 2025

Molexs story is interesting because they excelled at overcoming these cultural issues. The most common form of trading partner collaboration is purchase order collaboration. With PO collaboration, buyers send digital purchase orders over the network to suppliers or other trading partners. The buyers dont report to Mr. Gainsford.

Let's personalize your content