Modernizing the Warehouse with Andy Johnston

The Logistics of Logistics

OCTOBER 16, 2023

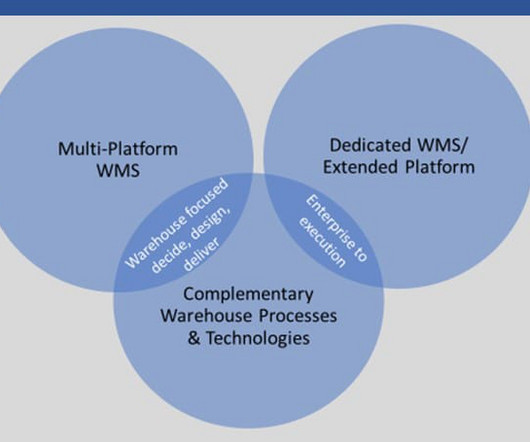

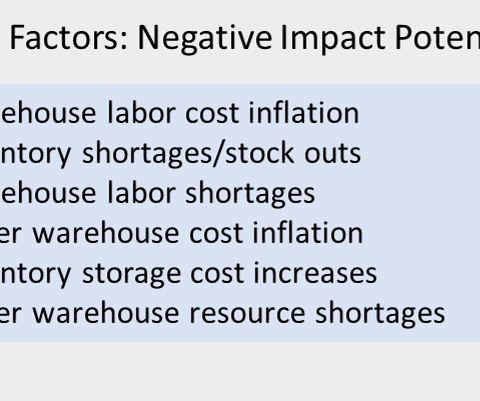

Andy Johnston and Joe Lynch discuss modernizing the warehouse. GEODIS is a company owned by SNCF group. Key Takeaways: Modernizing the Warehouse In the interview, Andy and Joe discuss labor challenges, wage inflation, competition, and the need to do more with less. 6 in its sector across the world. billion in revenue. GEODIS

Let's personalize your content