AI in Supply Chain Automation: Procurement to Logistics

Logistics Viewpoints

APRIL 14, 2025

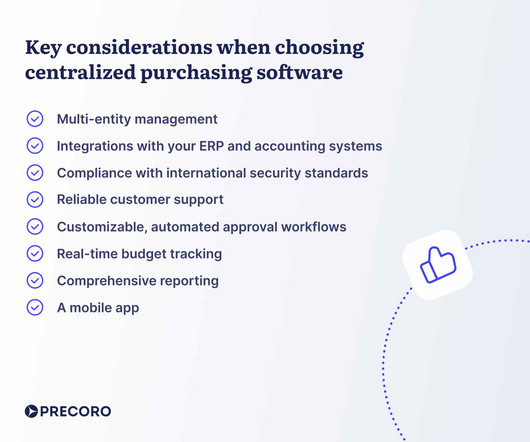

Use Cases: Spend Analytics: Machine learning models analyze historical purchasing behavior to identify opportunities for cost reduction, supplier consolidation, and policy enforcement. Integration allows seamless transitions from data insights to purchase approvals and execution.

Let's personalize your content