Kimberly-Clark’s Digital Transformation of Shipping

Logistics Viewpoints

AUGUST 2, 2021

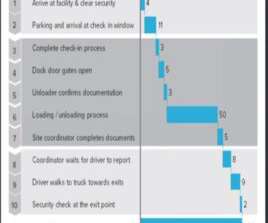

Driver dwell is a key source of driver dissatisfaction and contributes to the driver shortage. Weisenberger is leading their digitally enabled shipping initiative, she works in distribution operations rather than transportation. This is one of the company’s first steps to their digital transformation in shipping. What made Ms.

Let's personalize your content