The RocketFuel Story with Josh Beatty

The Logistics of Logistics

OCTOBER 29, 2024

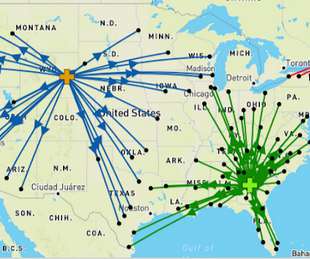

As Josh and his partner scaled Launch Fulfillment , they encountered some cash flow issues inherent in high volume parcel shipping that their ecommerce customers required. Client Access & Transparency: Provides client access to their shipping data for increased transparency and decreased administrative overhead.

Let's personalize your content