Why a Software Proof of Concept (POC) Is Better than an RFI

ToolsGroup

JUNE 8, 2021

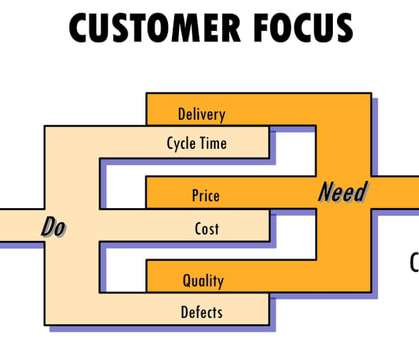

Solid online research and structured interviews with potential vendors are a better way to accomplish that initial shortlisting exercise. #5 6 Focus on the wrong metric. RFIs also assume the organization is focusing on the right metrics. 5 Blind spots. In volatile supply chain environments, forecasts are inherently inaccurate.

Let's personalize your content