Lean Logistics: Improving Efficiency in the Supply Chain

Unleashed

JANUARY 31, 2023

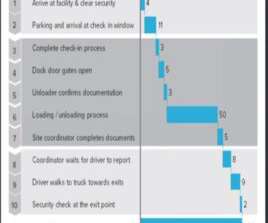

Lean logistics is a strategy designed to optimise supply chain efficiency by cutting out waste and maximising customer value. In this guide to lean logistics: What is lean logistics? This approach to supply chain management is a child of Lean Thinking – a business methodology that originated in Japan in the late 1980s.

Let's personalize your content