aioneers Recognized as a Representative Vendor in 2023 Gartner® Market Guide for Analytics and Decision Intelligence Platforms in Supply Chain

Aioneers

SEPTEMBER 13, 2023

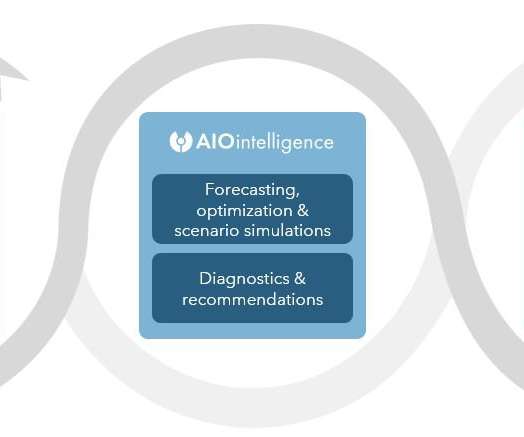

aioneers, a fast-growing provider of AI-powered supply chain management software has been listed as a Representative Vendor in the 2023 Gartner® Market Guide for Analytics and Decision Intelligence Platforms in Supply Chain. We believe that this recognition signifies aioneers' commitment to excellence, innovation, and its position as a competitive player in the market.

Let's personalize your content