INTERPHEX 2023: Finding Contract Pharma & BioPharma Manufacturing & Supply Chain Efficiencies

QAD

APRIL 13, 2023

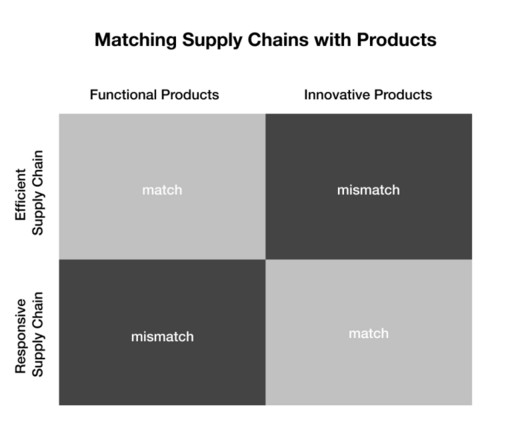

While Contract Pharma & BioPharma manufacturers continue to experience an increase in demand for more projects, new challenges are emerging from nearly every angle including new regulatory and quality requirements, workforce shortages and of course, supply chain disruptions. is likely to reach 2.1

Let's personalize your content