Supply Chain & Logistics News Round-Up (December 30th 2024- January 2nd 2025)

Logistics Viewpoints

JANUARY 3, 2025

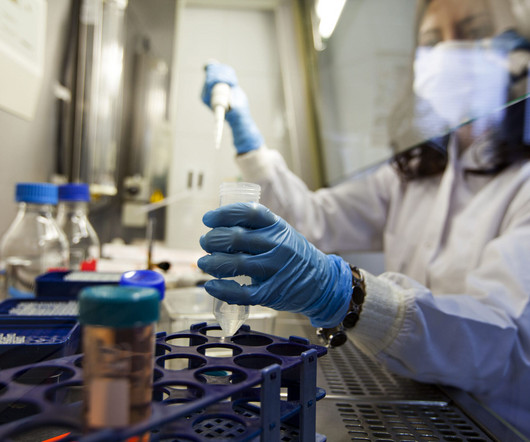

The DOE is still issuing large federal loans to startup companies, Novonix a synthetic graphite startup just received a $755 million loan to support its mission and reach its goal of producing 31,500 metric tonnes of synthetic graphite. The facility aims to reach full production capacity by the end of 2028.

Let's personalize your content