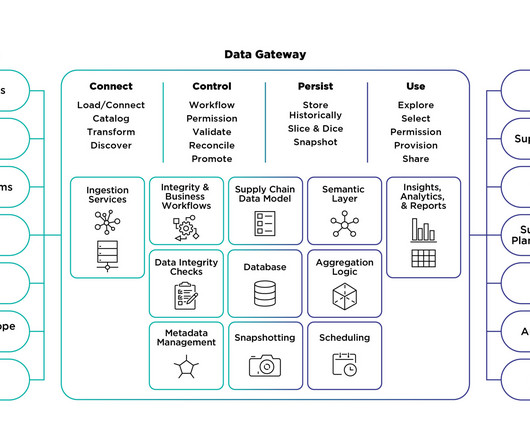

10 Ways A Data Gateway Improves Time to Value Across Your End-to-End Supply Chain

Logistics Viewpoints

MARCH 11, 2025

For example, with a data gateway, a supply planner gains accelerated access to customer orders, inventory levels, and transportation schedules, all in one place, to increase the user experience of making the right choice to identify inefficiencies and make better, more informed decisions.

Let's personalize your content