A New Decade: Give Science A Chance

Supply Chain Shaman

DECEMBER 28, 2020

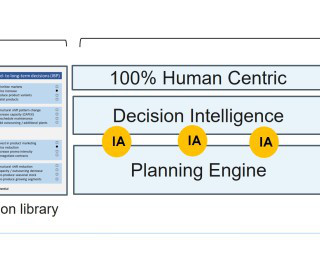

The first story is about a large regional food manufacturer. The team was attempting to be customer-centric by modeling an item by customer at a DC level. The second story is about a regional beverage manufacturer. This was the case for the client stories that I will share in this blog. Let’s Be Customer Centric.

Let's personalize your content