ZF’s Transition from Lean to Supply Chain Resilience

Logistics Viewpoints

OCTOBER 31, 2022

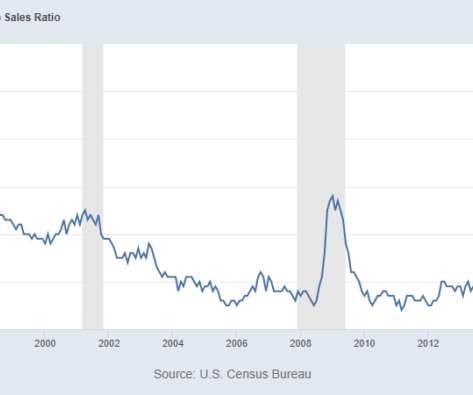

The Transition from Lean to Resilience. No industry has been more committed to lean practices than the auto industry. Lean cuts inventory out of the supply chain. But when things go wrong, lean can lead to large losses in sales because there are no just-in-case inventory buffers.

Let's personalize your content