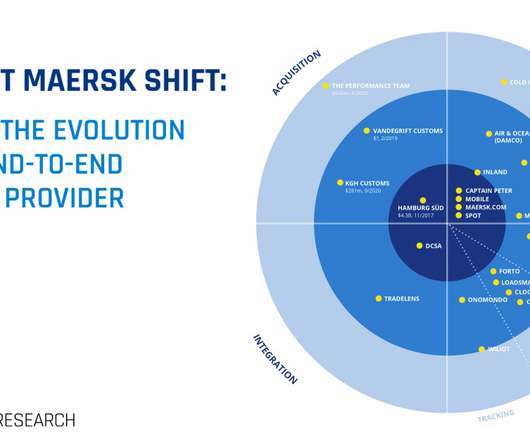

The Journey to End-to-End (E2E) Supply Chain Visibility Is Ongoing

Logistics Viewpoints

JANUARY 12, 2023

It means being able to see where a shipment or an order is while it’s in transit — whether on a truck, a railcar, an ocean liner or a cargo plane — anywhere in the world. According to McKinsey, an auto manufacturer, on average, has around 250 tier-one suppliers – and 18,000 across the full value chain.

Let's personalize your content