The CHIPS and Science Act of 2022: What It Means for the Future of Manufacturing

ivalua

NOVEMBER 8, 2022

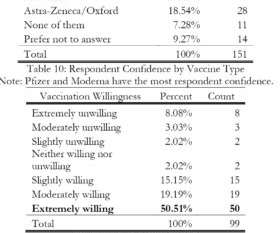

US Government Passes the CHIPS Act to Increase Semiconductor Manufacturing and Research. The CHIPS Act was created in response to pandemic-induced shortages of semiconductors and other critical manufacturing supplies, causing widespread disruption to supply chains across the country. . Part A: Manufacturing in the U.S.

Let's personalize your content