The Future of Autonomous Supply Chains Part 1: Autonomous Shipping

Logistics Viewpoints

JUNE 12, 2024

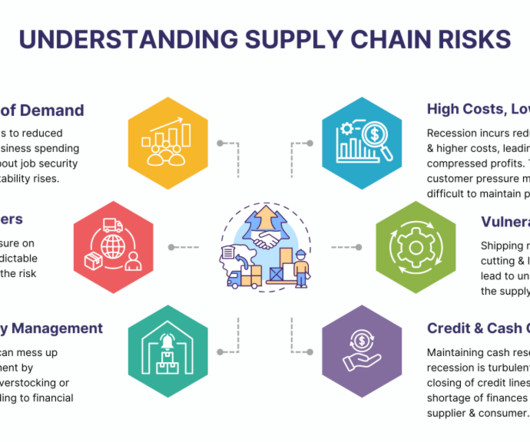

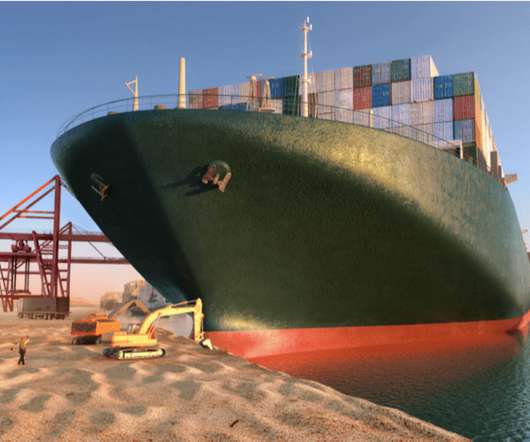

Autonomous supply chains can help businesses by enabling faster and more accurate demand forecasting, optimizing inventory levels and distribution networks, automating warehouse and delivery operations, and enhancing customer service and satisfaction. Degree two: Remotely controlled ship with seafarers on board.

Let's personalize your content