Supply Chain Normalcy? Think Again.

Supply Chain Shaman

APRIL 18, 2023

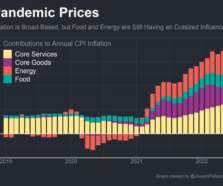

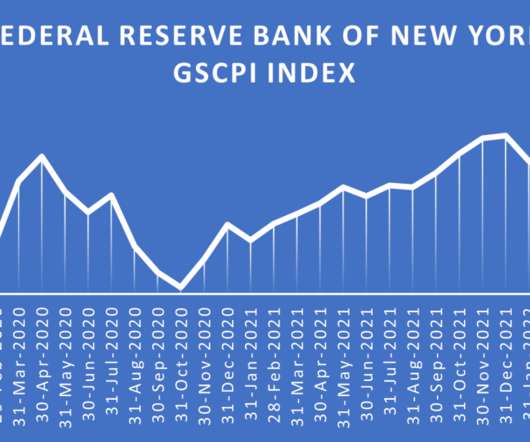

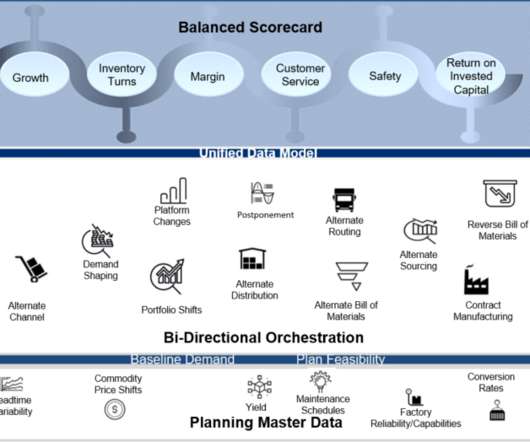

Over four-hundred days of war in Ukraine. Growing tensions between China and trading partners. As consumer spending fell, the days of escalating ocean freight and extreme shipping variability eased this year. In the face of variability, this is two-to-six weeks too long to make allocation or procurement decisions.

Let's personalize your content