Supply Chain Resilience Core Capacities

MIT Supply Chain

AUGUST 17, 2021

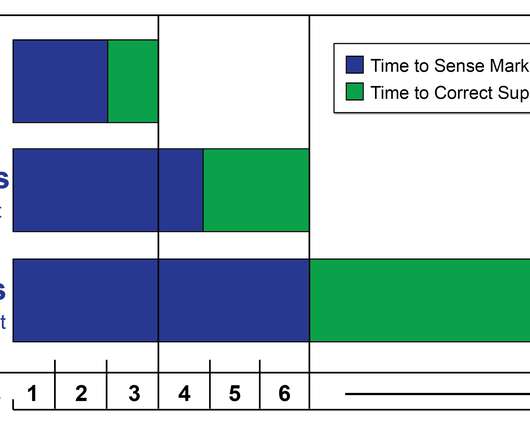

Part 2: Lessons from Comparing Disruptions In the previous post in this two-part series, The 7 Core Capacities of Supply Chain Resilience , we identified the core capacities that are the building blocks of supply chain resilience. Note that the seven core capacities are assessed as to whether there is a loss of capacity or not.

Let's personalize your content